Everything You Need to Know About Hydraulic Systems

| Daniel Webmarketingguru

The development of hydraulic technology since the nineteenth century has been sensational. The fundamental benefits of the hydraulic system are the simple and robust energy move, adaptability, and the capacity to duplicate power transmission for different modern purposes. Hydraulic systems are utilised in heavy machinery, ranching, construction, mining, car, and aviation industries. We can say that fluid power in a closed circuit system can contend effectively with mechanical and electrical frameworks. Hydraulic systems can give power ranging from mere kilos to several tons. But what exactly is the hydraulic system? Let's find out!

What is a hydraulic system?

Hydraulic systems make use of pressurised liquids and their mechanical properties to perform work. They are versatile and used in numerous applications from heavy steel to paper plant and manufacturing industries. There are different types of hydraulic systems today but they all work on a similar idea, i.e., utilising compressed fluid hydraulics to do work.

How does a hydraulic system work?

In a hydraulic system, pressure is applied to push the liquid through the apparatus. The compressed liquid generates power through the conversion of mechanical energy into fluid power. This power is one of the strongest and can easily lift heavy weights. Every hydraulic system works on the principle of Pascal's law which states that: "Pressure applied to a bound liquid will be transmitted undiminished throughout the liquid and the vessel walls." The rule of Pascal's law is acknowledged in a hydraulic system by the hydraulic liquid that is utilised to send the energy starting with one point and then onto the next.

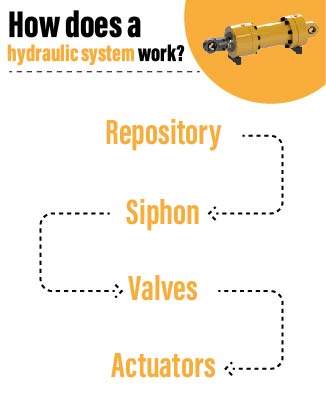

The significant parts that make up a hydraulic system are the reservoir, siphon, valves and actuators.

-

Repository

The hydraulic reservoir is used to hold a volume of liquid, move heat from the framework, and permit strong pollutants to settle and work with the arrival of air and dampness from the liquid.

-

Siphon

The hydraulic pump siphon transforms mechanical energy into hydraulic energy through the fluid which is the transmission medium. There are a few hydraulic pump siphons, including gear, vane and cylinder, all designed for different applications. All hydraulic siphons work on a similar principle: uproot liquid volume against a safe burden or strain.

-

Valves

Hydraulic valves are utilised to begin, pause and direct liquid stream. They are composed of poppets or spools and can be compelled through pneumatic, water-driven, electrical, manual or mechanical means.

-

Actuators

Hydraulic actuators are the final product of Pascal's law. This is where the hydraulic energy is changed back completely to mechanical energy. This is made possible through the utilisation of a hydraulic chamber that changes over pressure-driven energy into straight movement and work, or a pressure-driven engine that converts hydraulic energy into rotational movement. Likewise, hydraulic siphons, water-driven chambers and hydraulic engines have a few different subtypes, each designed for specific applications.

Advantages and Disadvantages of Hydraulic Systems

Hydraulic systems are generally easy-to-control and simple to operate. This makes them a popular choice for large operations. Their ability to handle heavy loads makes them perfect for a variety of industrial and mechanical applications like excavator hydraulics and machine hydraulics. However, they have their drawbacks too. For instance, even the tiniest of leaks in the system can render it inoperable and in need of repairs. That being said, let us look at the pros and cons of a hydraulic system.

Benefits

- Self-lubricating system

- Excellent power-to-mass ratio

- Simple and easy to operate

- Uses fewer moving parts

- Allows very accurate application of power

- Can be controlled manually or electrically

Disadvantages

- Contaminants in the fluid affect performance

- A small leak can shut down the system

- Wrong hydraulic fluid choice will damage the system

- Significant power loss over a longer transmission distance

Hydraulic systems are designed to handle loads several times their weight besides several other applications in automobiles, aircraft, heavy machinery, fuel pumps, and even your humble dishwasher. They make handling heavy objects very easy and simple. Despite their drawbacks, hydraulic systems continue to be in high demand as a result of their versatility and ease of use.

Buy Hydraulic Products and Parts Online in Australia

Hydraulic-powered systems have become critical components of modern mining, mechanical, aviation, and space innovations. Thanks to the advancements made in hydraulic energy transmission systems, the industry is becoming increasingly proactive. Hydraulic power units, industrial hydraulics, and many other heavy hydraulic units have found common applications in various capacities across many industries today.

Flowline is one of the leading suppliers of hydraulic systems and parts in Australia. We have 20 years of experience in the industry and work with several leading manufacturers. Our focus is always on meeting the changing expectations of our clients as quickly and efficiently as possible. The team prides itself on offering unmatched customer support and quality products at the best prices.

To know more about our hydraulic supplies and services, you can call us on 1800 239 399 or email us at info@flowline.com.au. Our support team is here to assist you.